Zund File Preparation Guideline

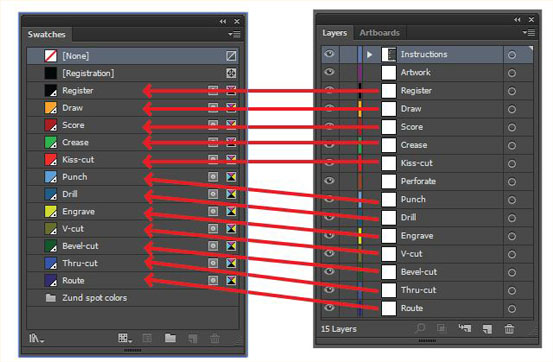

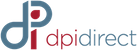

To prepare a file for ZUND use the pdf (ZUND_LAYOUT_FILE) attached below as this will have all the correct swatches and layers it requires.

If you need a specific Operation (Drill, Thru-cut, Kiss-cut,Crease etc.) to be done on Our digital Cutter (Zund), place the dieline in the corresponding layer along with the corresponding Swatch color for the desired operation.

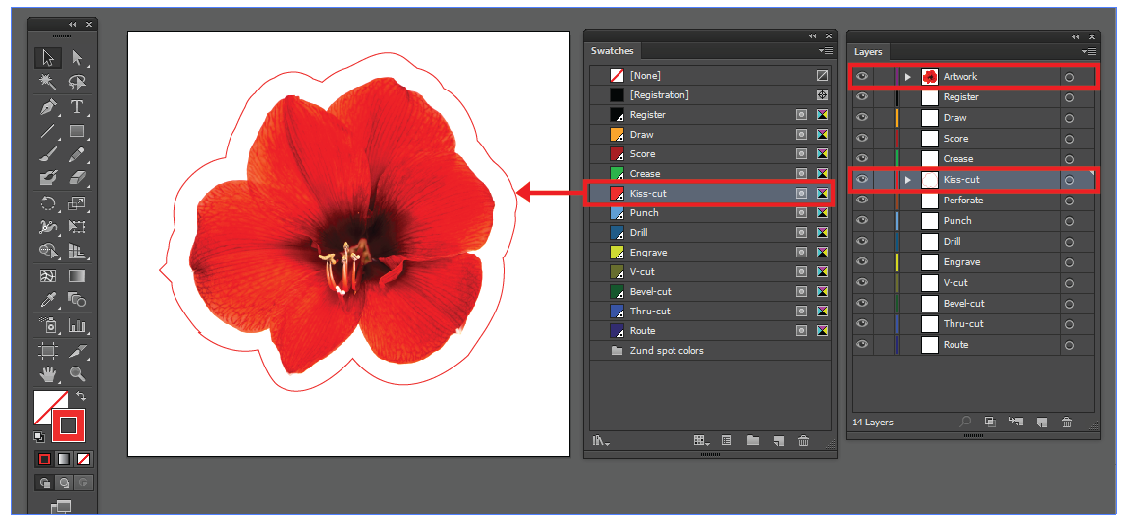

Example 1: Kiss-cut

a. If you need your product with a kiss cut.

- i. Place you art in the Artwork Layer

- ii. Place your die-line in the Kiss-cut Layer

- iii. Assign the Kiss-cut swatch color to your stroke or line of your dieline

b. This operation is mainly done for stickers or decals

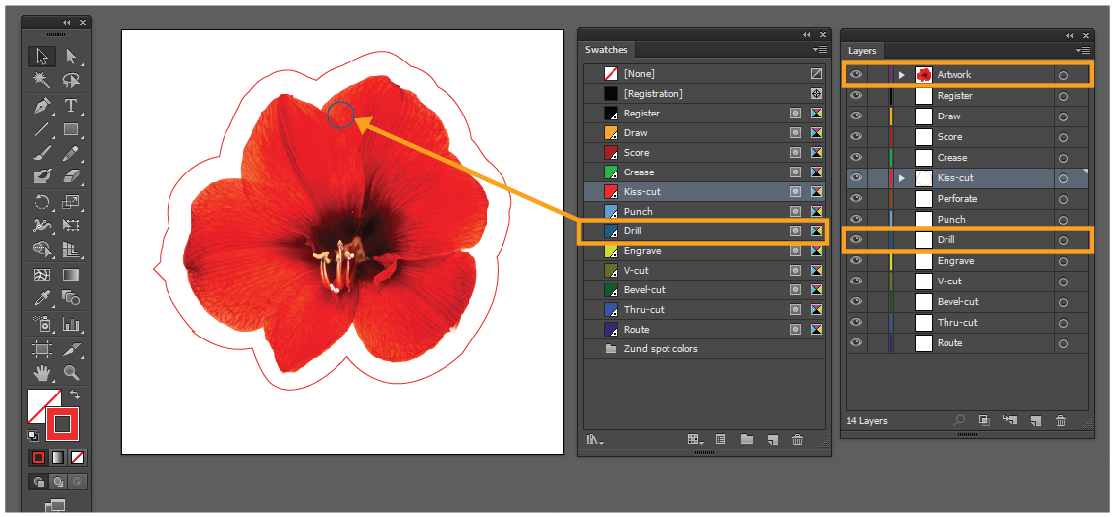

Example 2: Hole Drill

a. If you need a Hole Drill in your product

- i. Place your art in the Artwork Layer

- ii. Place your die-line in the Drill Layer

- iii. Assign the Drill swatch color to your stroke or line of your dieline

b. This operation is mainly done for hard materials I.E. 6mm Sintra, ACM (Aluminum Composite Material, commercially known as Dibond), Gator Board.

Please refer to our board swatch deck.

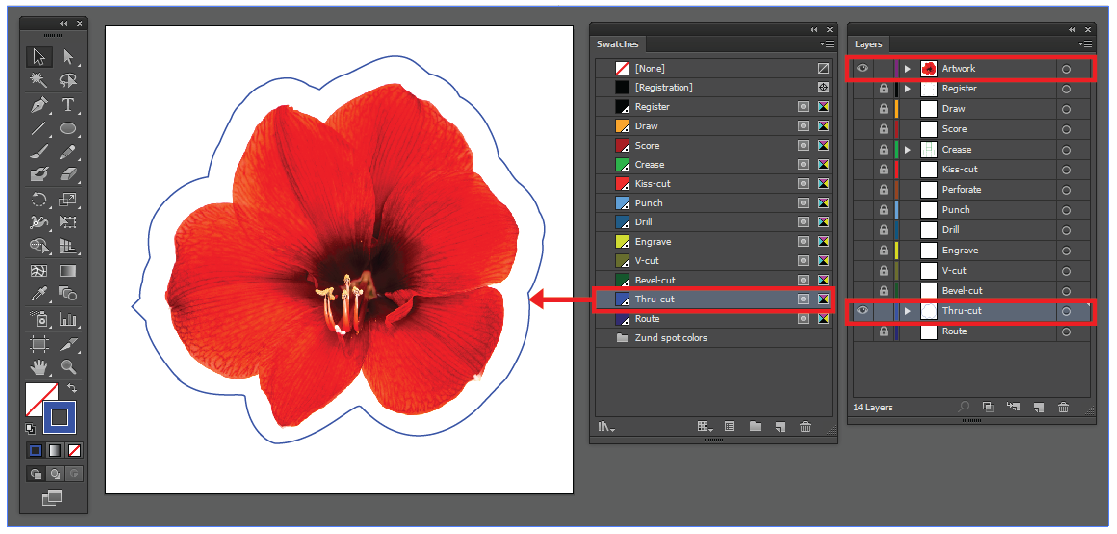

Example 3: Thru-cut

a. If you need a Thru-Cut on your product

- i. Place you art in the Artwork Layer

- ii. Place your dieline in the Thru-cut layer

- iii. Assign the Thru-Cut swatch color to your stroke or line of your dieline

b. This operation is mainly done for most materials, EXCEPT Thick materials like 6mm Sintra PVC, Dibond, Gator Board.

NOTE: PLEASE READ THE FOLLOWING POINTS CAREFULLY BEFORE YOU PROCEED.

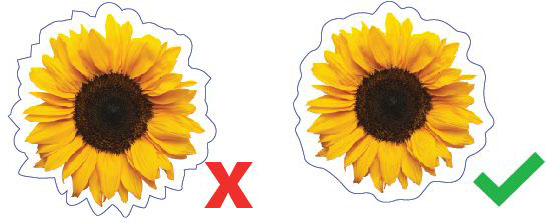

1. Please have your dieline to be as smooth as possible depending on the material or thickness of the board being used the outcome might defer with complex intricate cuts.

2. For our Digital Cuter If your product require multiple operations please make sure that all of the dieline marks are assigned to the correct Layer with the corresponding color swatch for the operations.